Why Chrome Plating?

It's hard to beat the appeal that chrome plating brings to emblems, trim and components. Making custom chrome decals and emblems look shiny, sleek and desirable, the plating process adds a luxurious finish to any product.

Chrome plated components are durable and easy to clean, always shining up to a beautiful gleam when cleaned. For this reason, chrome plating is often used for automotive parts, tools and kitchen utensils to achieve a bright, smooth reflective surface finish appearance.

Choose from the following chrome emblem finishes:

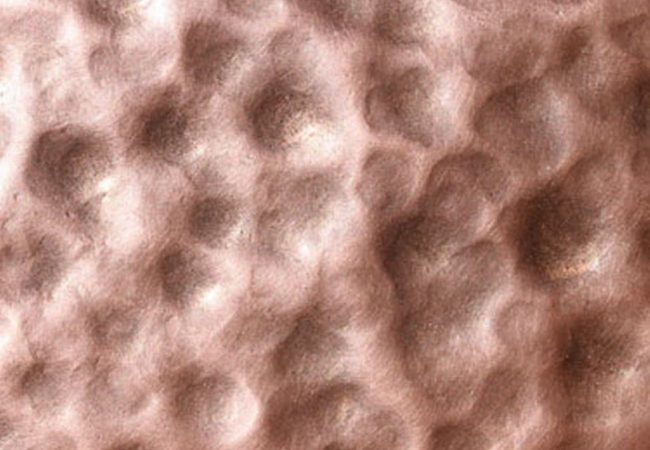

Textured finish:

- Warty texture

- Micro Hammered texture

- Fully Hammered texture

Metals:

- Silver – Matte

- Silver - Glossy

- Nickel - Matte

- Gold - Glossy

- Bronze - Natural

Antique look:

- Antique Copper - light

- Antique Bronze - light

- Antique Bronze - medium

Chrome plating process is carried out by electroplating a thin layer of chromium onto a plastic or metal object. This layer of chrome plating on plastic or metal can be applied for one of the following purposes:

- decorating

- easing the cleaning process

- increasing surface hardness

- providing resistance to corrosion

CONTACT US

The Chrome Plating Process

Plastic chrome plated products allow for much greater flexibility in terms of the range of shapes and level of detail that can be molded, compared to metal. Withstanding the environment well, yet remaining lightweight, plastic chrome becomes an ideal choice for emblems and nameplates, representing quality with practical functionality. When used on vehicles in place of metal, weight and hence fuel costs are reduced.

Decorative chrome plating process is often applied over a layer of nickel to provide the corrosion resistance and reflective properties of the final chromed product. The original mold and the nickel layer need to be of very high quality, with accurate finishes, since the final chrome layer magnifies any errors rather than covering them. Premium Emblem Co.ltd, one of the world’s leading chrome plating companies, conducts in-house injection molding and nickel plating to guarantee the quality of the entire process.

Additional finishes can be applied to the chrome plated emblems, as required, for example, an opaque or transparent color. Other finishes include gloss or matte, silver, bronze, nickel or gold chrome plating metallic looks, an antique effect or special surface texturing.

Chrome plating process adds a modern or dated, functional or ornate, eye-catching or unobtrusive. It’s no wonder that this very flexible process, with all its added aesthetic benefits, has such a wide variety of applications and uses.

CASE STUDY - PremiumEmblem Co.ltd, chosen suppliers of Mercedes Benz.

Adhering to Strict Guidelines

Mercedes-Benz, as the logo suggests “the best or nothing,” has extremely strict quality control requirements. These are placed upon by the German automobile industry, VDA controlling system.

Mercedes Benz Sport Coupe

The quality of this chrome plated badge is in accordance with the DIN EN ISO9227-CASS requirements. All of our finished products go through rigorous testing to determine durability and precision metrics.

An Exterior To Match The Inside

Mercedes Benz C250, Coupe Sport. Our final result involved chrome plating a plastic emblem with a black and red finish.

Call Premium Emblem NOW for all your emblem and nameplate requirements